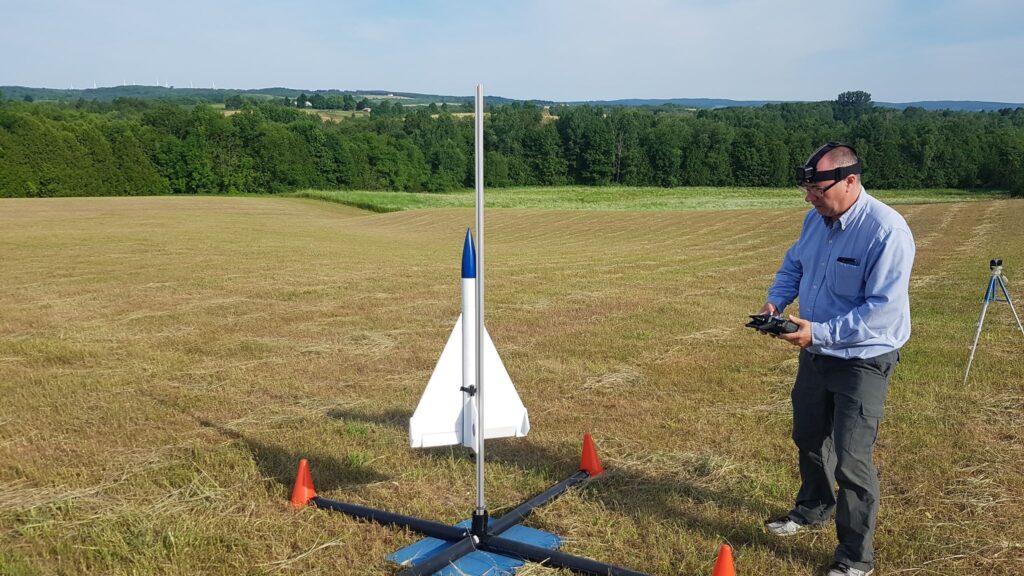

Blue Dart Delta II Assembly

The Blue Dart Delta II is a fiberglass experimental RC rocket plane. It is based on the original Blue Dart Delta all foam rocket plane. The body tube (BT-80) was glassed with 1-ply of BID cloth and covered with peel ply. Paper templates were made for the delta wings, winglets, vertical stabilizer and ventral fin …