Trimmed and sanded the transition piece then removed the inside foam and tape.

Workshop temperature 24 deg C and humidity 55%.

Mixed a batch of epoxy using 138g resin and 52g hardner.

Poured some of the epoxy in a separate mixing cup and added glass balloons. Poured a bit of the micro into a smaller cup and added more glass balloons to make dry micro.

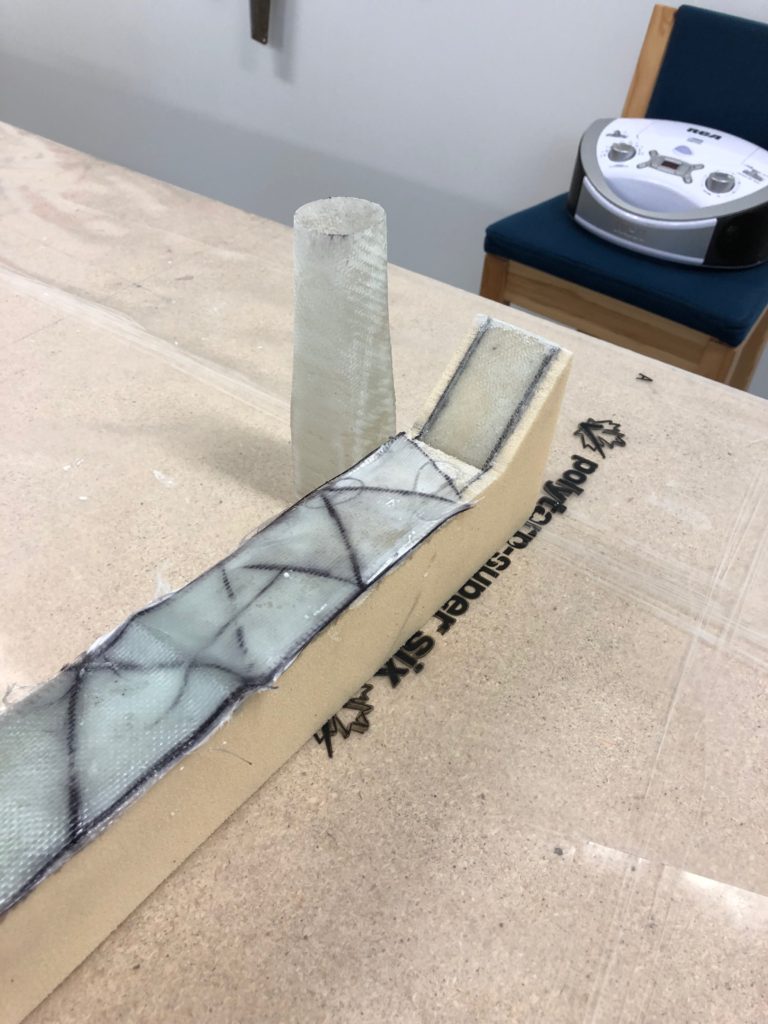

Used the dry micro to fill in any lower areas in the shoulder brace foam then spread micro over all the foam and wet out any mating glass surfaces with epoxy.

Mixed a 2nd batch of epoxy using 110g resin and 42g hardner.

Proceeded to lay up 2-ply BID cloth over the shoulder support and peel ply where required.