Workshop temperature was 24 deg C and the humidity was 58%.

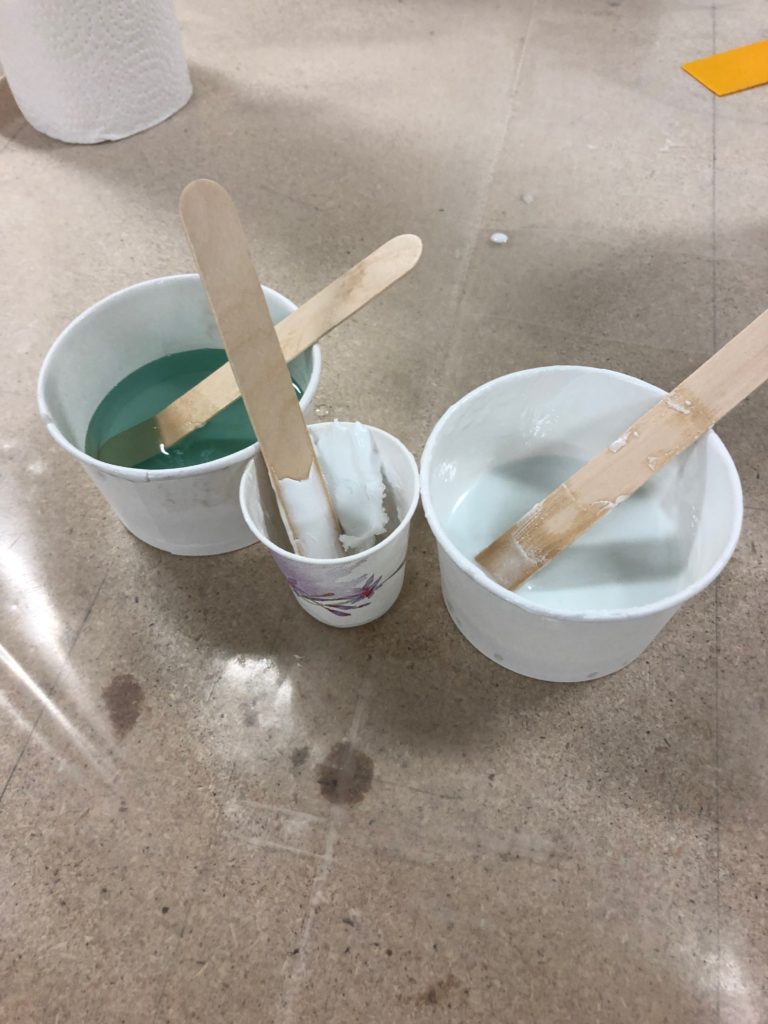

A batch of epoxy was mixed using 30g resin and 11g hardner. Epoxy was applied to 2-ply BID cloth then the cloth was placed around the heat duct transition piece and trimmed to size.

Another batch of epoxy was mixed using 138g resin and 52g hardner. The UND cloth was wet out with epoxy and seven 2″ strips cut to size and assembled into 7-ply.

Wet micro was mixed with some the epoxy and applied to the top of the aft heat duct. A smaller batch of dry micro was mixed using the wet micro and applied on each side of the aluminum tube.

The 7-ply UND strip was applied to the top of the heat duct.