Trimmed and sanded the rough edges at the top back side of the seatback/shoulder support.

Sanded a radius on the forward corner of the shoulder brace.

Trimmed and sanded the headrests.

Vacuumed the sanding dust and cleaned up the workshop.

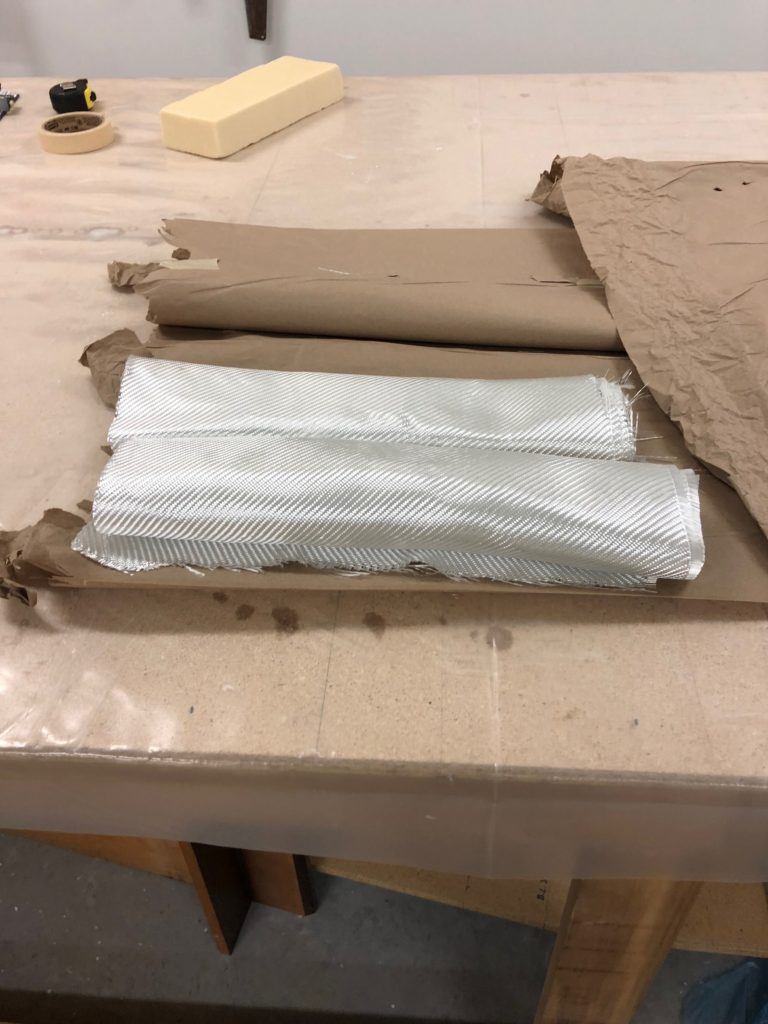

Cut 2 ply of BID cloth to size to cover the shoulder support.

UND cloth was prepared for the 7-ply heat duct reinforcement.

A transition piece (heat duct to engine) was carved out of urethane foam. The piece is 6″ long and 1.5″ x 1.5″ square at the bottom and 1 7/16″ diameter at the top. The transition piece was covered with black tape so the foam won’t stick to the fiberglass.