Workshop temperature was 24 deg C and 58% humidity.

32g resin and 12g hardner was mixed with micro bubbles. The micro mixture was applied to the unglassed side of the 5 spacers using a squeegee.

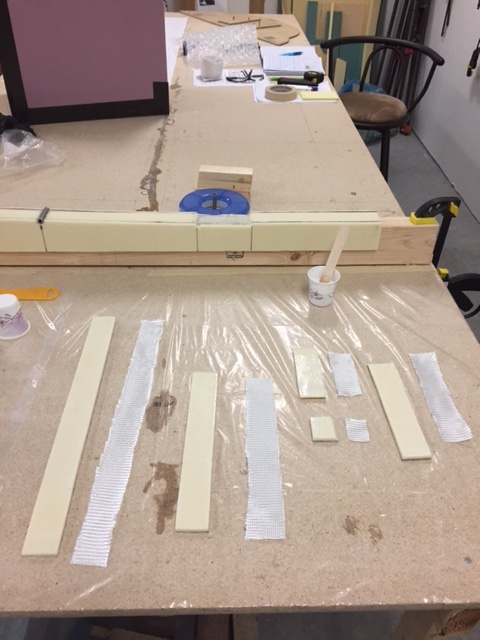

The BID fiberglass cloth was positioned on each of the spacers.

15g resin and 6g hardner was mixed and applied onto the BID cloth with a paint brush.

The spacers were left to cure.