Prepared a temporary jig to align both triangular braces and for spacer positioning. Inserted small nails through the pre-drilled holes in the bottom triangular brace to hold spacers in place and inserted the aluminum tube (seatbelt anchor) to help ensure alignment between braces.

Trimmed and sanded the spacers.

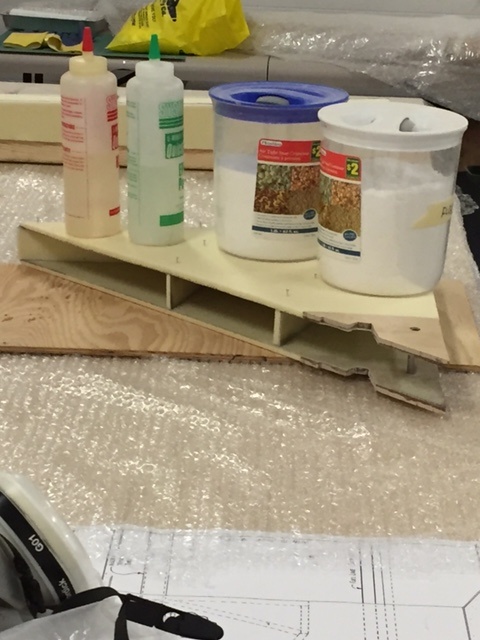

Positioned the spacers on the bottom triangular brace with the bottom nails holding them in position.

With the workshop temperature at 25 deg C and the humidity at 58%, I mixed 18g resin with 7g hardner and some flox. The flox mixture was applied to the top edges of all 5 spacers. The top triangular brace was positioned on top of the spacers (unglassed side up).

Small nails were inserted into the pre-drilled holes to keep the triangular brace and spacers in position during cure.

Weight was added to the top brace to hold it tightly against the spacers during cure.

The wooden jig was removed.