Workshop temperature was 25 deg C and humidity 50%.

A batch of epoxy was made using 140g resin and 53g hardner.

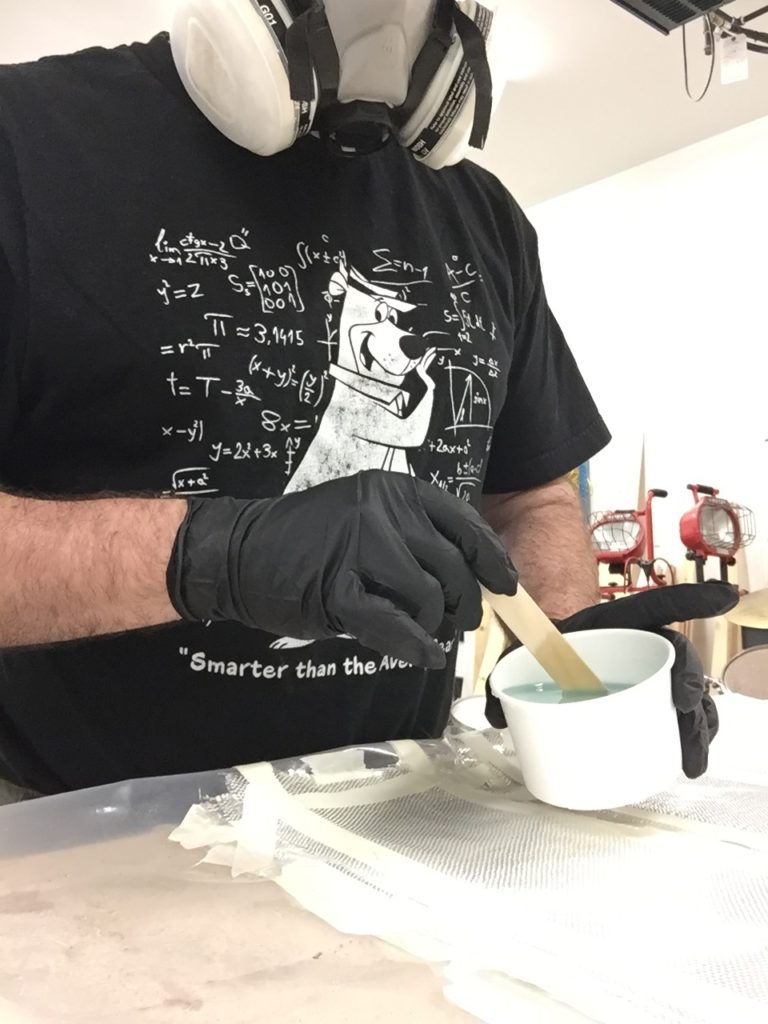

The 6-ply of UND cloth was wet out with the epoxy.

Epoxy was applied to the bulkheads where the layups are positioned.

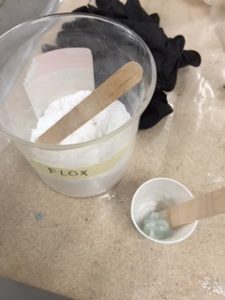

Flox was mixed with the epoxy in a small cup then applied to the joint where the 6-ply will go.

Another batch of epoxy was made using 62g resin and 24g hardner.

The layups were cut out using electric scissors and positioned on the aft side of the forward landing gear bulkhead.

The layups were covered with peel ply and left to cure.