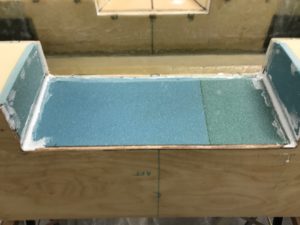

Sized paper (templates) to fit in the forward and aft scoop sections such that it will be 1/4″ past the edges and >3/4″ onto the bulkheads.

Cut 2 ply of BID cloth to the size of the templates.

Cut peel ply.

Workshop temperature 24deg C and humidity 52%.

Mixed a batch of epoxy using 152g resin and 58g hardner.

Wet out the 2-ply BID cloth for the aft scoop section.

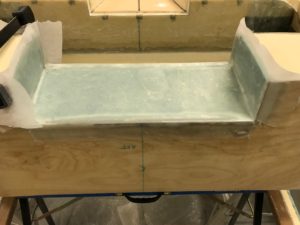

Mixed a small batch of dry micro to fill any gaps in the aft scoop foam and to fill the corners.

Mixed a batch of micro to cover the foam. Used epoxy to wet the bulkheads where they overlap with the cloth.

Placed the 2-ply BID cloth in the scoop and scissor trimmed the edges to ~1/4″ past the edges.

Applied peel ply and more epoxy.