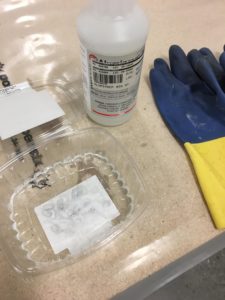

Mixed a 1:1 ratio of water and Alumiprep#33 in a plastic container and dipped the 16 aluminum inserts into the mixture for abour 3 minutes then rinsed them off with water.

Covered the 16 aluminum inserts with Alodine 1201 and let them dwell in the Alodine for about 3 minutes then rinsed off the inserts with water.

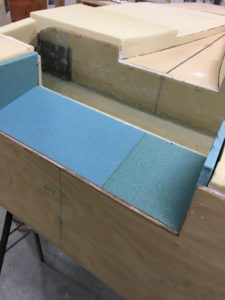

Trimmed and sanded the fiberglass to be flush with the inboard sides of the plywood braces.

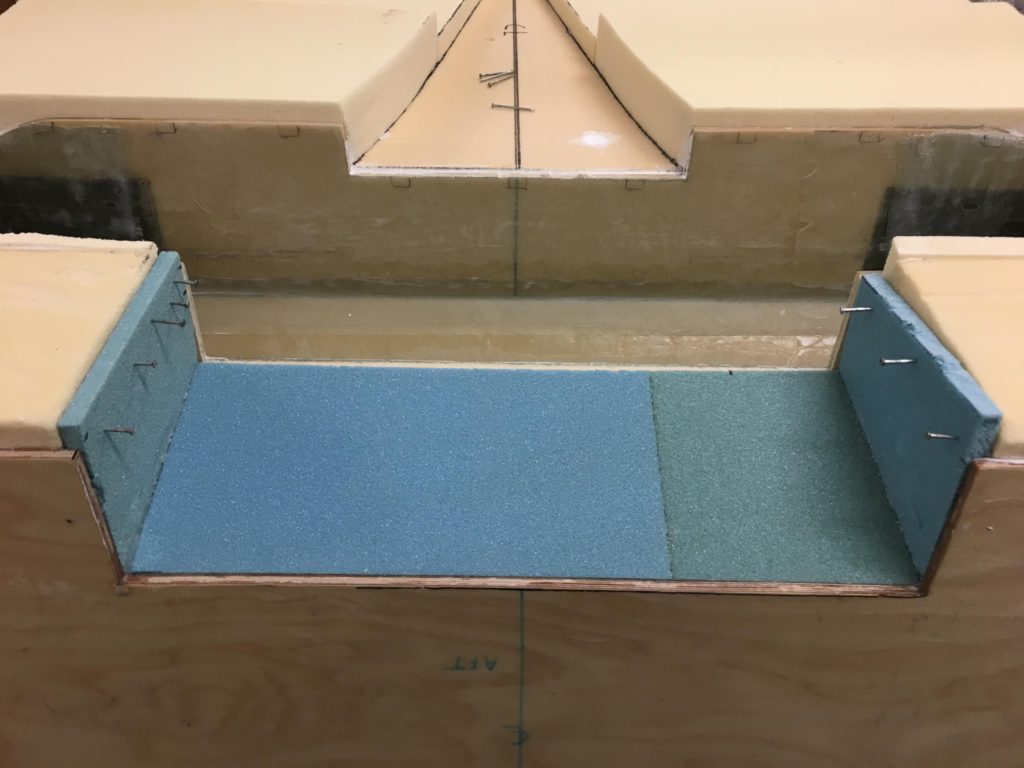

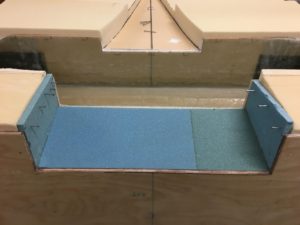

Shaped 3 pieces of 3/8″ PVC foam to fit between the 2″ blocks, the firewall, and the aft landing gear bulkhead.

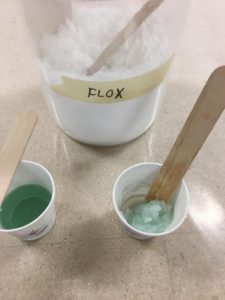

Shop temperature 25 deg C and humidity 64%. A small batch of epoxy was made with 42g resin and 16g hardner. Flox was mixed in and applied to the surfaces of the bulkheads and PVC foam as applicable to permanently position the PVC foam. Nails were added to secure the PVC foam while the flox cures.

The PVC foam was positioned with a 1/8″ misalignment so that a recess for the landing gear cover can be made later.