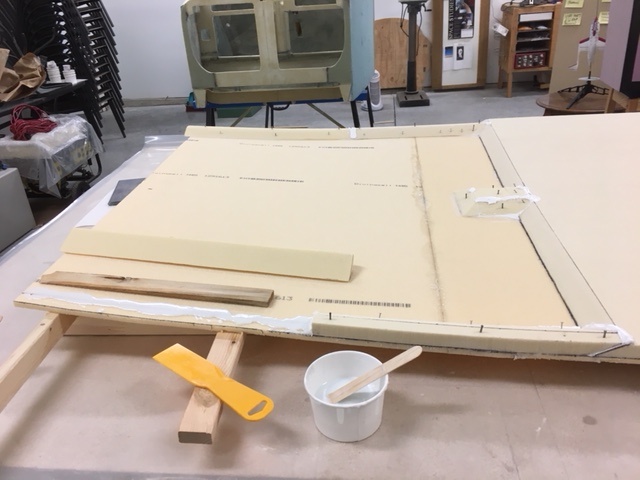

Micro the aft aircraft floor spacers in place:

Workshop temperature was 25 deg C and humidity 35%.

122g of resin was mixed with 46g of hardner and glass bubbles to make a batch of micro. Some of the batch was poured into a second mixing cup and more glass bubbles were added to the 2nd cup to make a small batch of dry micro.

Micro was applied to all the mating surfaces and the spacers were positioned in place with small nails which will be removed after the micro cures.