I placed the fuselage sides upside down at the approximate width apart and confirmed that the top longerons are level.

I noticed a few gaps between the top longerons and the fiberglass so I filled them with flox.

Shop temperature was 74 deg F and the humidity was 49%.

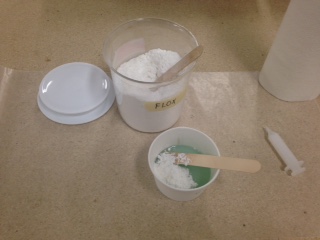

32g resin was mixed with 12g hardner and flox. I used an industrial syringe to fill any gaps and then used a popsicle stick to smooth over the surface and remove any excess flox.