The locations for the canopy hinges were marked on the longeron.

Two pieces of MS20001-P6 hinges were cut to10″ lengths.

The hinge halves were separated.

Sanded the bonding surfaces of the hinges and the longeron. 220 grit on the hinges and 36 grit on the longeron.

Tape was applied to the hinges to keep the epoxy out of the hinges.

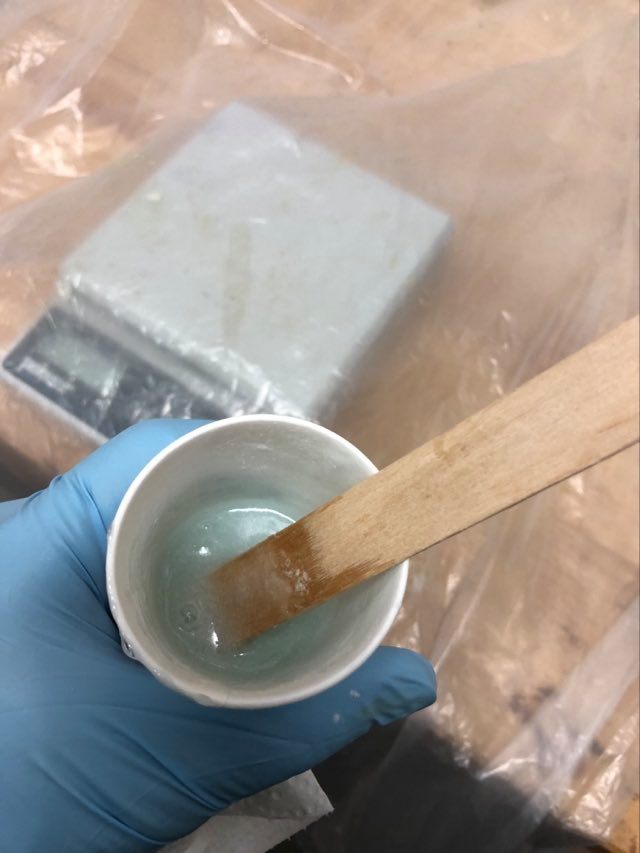

With the workshop temperature at 24 deg C, a small batch of flox was mixed using 15g resin and 6g hardner.

Flox was applied to the longerons and the hinges were positioned on the longerons and clamped in place such that both hinges are in the same plane.

Drilled #12 holes through the canopy hinges and longeron and countersink.

Installed machine screws, washers, and nuts to secure the two canopy hinges in place.