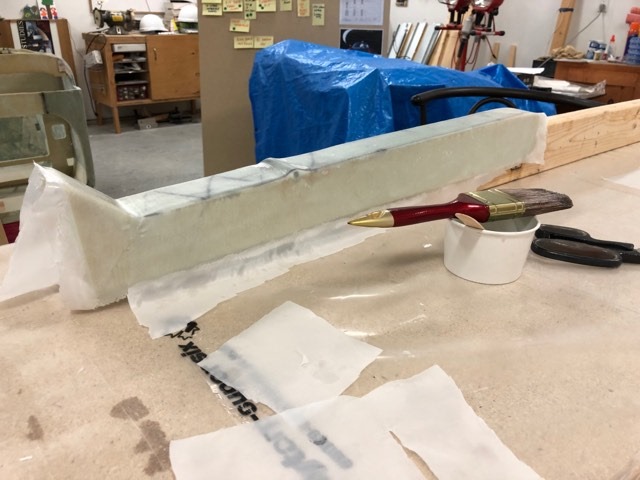

Trim, sand, and vacuum the aft heat duct.

Cut 2-ply BID cloth @ 45 deg orientation and a piece of peel ply to cover the layup.

Workshop temperature 24 deg C and 40% humidity.

A batch of epoxy was mixed using 188g resin and 72g hardner.

Epoxy was brushed onto the top glassed portion of the heat duct.

A batch of micro was mixed and applied to the foam surfaces of the heat duct.

A small batch of dry micro was applied where the top surface meets the ramp at the rear of the heat duct.

Two layers of BID cloth were applied on with epoxy, followed by peel ply.