Permanent installation of the seat brace and the heat duct.

Outside air temperature was -20 deg C and the workshop temperature was +25 deg C (humidity 32%).

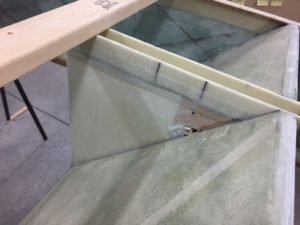

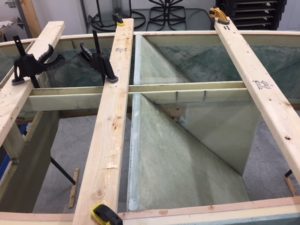

The seat brace/duct assembly was positioned in place and a marker was used to outline where it mates with the instrument panel and seatback.

62g resin and 24g hardner were mixed with flox and applied to the instrument panel and to the seatback.

The seat brace and heat duct were placed in position and 2 x 4s were used to clamp the assembly in place during cure. The bottom of the heat duct was confirmed to be flush with the instrument panel, with the seatback, and with both lower longerons.

Flox was applied to all outside joints and excess flox was wiped away.