Glassed the 2nd side of the seat brace and repaired the bottom of the instrument panel.

Shop temperature was 25 deg C and the humidity was 48%.

168g resin was mixed with 64g hardner.

A small portion of epoxy was poured into 2 small cups. Glass bubbles were added to one cup to make dry micro and flox to the other cup.

Epoxy was also placed in a larger cup and glass bubbles added to mix up a micro slurry.

The bottom of the instrument panel was repaired with the flox.

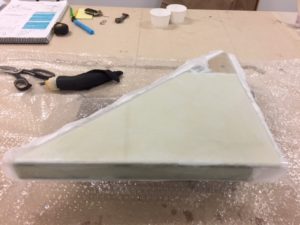

Dry micro was applied to the seat brace followed by the micro slurry.

Two layers of BID cloth was applied to the seat brace and trimmed.

Peel ply was placed over the layup for cure.