Workshop temperature was 25 degC and humidity 53%.

A batch of epoxy was mixed with 132g resin and 50g hardner.

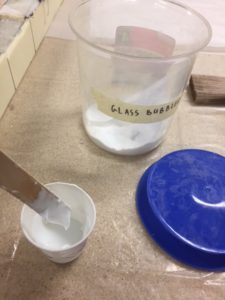

Some of this epoxy was poured into a small cup and micro balloons added to make a batch of micro.

A small portion of the micro was poured into another cup and more micro balloons added to make a small batch of dry micro.

Holes and edges were filled with the dry micro.

The foam was covered with micro and the wood was covered with epoxy.

2 layers of BID cloth were applied to the triangular brace and trimmed with electric scissors.

Peel ply was placed on top of the layup and epoxy added. Wax paper was placed over the peel ply, then a piece of wood with weights on top while the glass cures.