Started the work session with coffee.

Trimmed and sanded the edges of the 7-layer UND layup on the heat duct and the edges of the 2-layer BID layup on the seat brace.

Cut the 2 holes for the electrical channel out of the firewall. Cut and sanded the firewall longerons, and stringers to be flush with the firewall. Trimmed and sanded the firewall 2″ taped joints.

Removed excess wood and flox from bulkhead F22 and removed excess epoxy from the bottom of the longerons and front seatback.

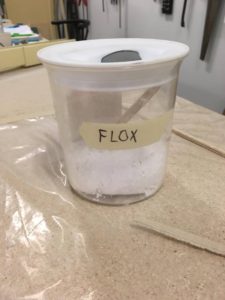

Workshop temperature was 23 deg C and humidity 58%. Mixed 15g resin with 6g hardner and flox. Floxed a small piece of wood (same wood as used for the permanent firewall) to build up the bottom of the instrument panel. Floxed in place, clamped, and left to cure.

Ended the work session with a beverage of the sociable nature.