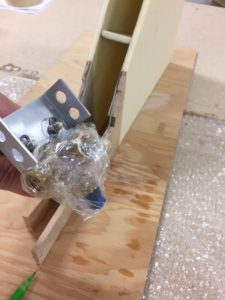

The fuel valve was covered in saran wrap to avoid it being floxed in place since it needs to be removable.

The bracket was traced onto the triangular brace where the flox is applied.

Workshop temperature was 25 deg C and the humidity 56%.

15g resin, 6g hardner, and flox were mixed together.

The 3/8″ x 2″ aluminum tube was floxed into place.

Flox was applied to the triangular brace and the fuel valve and bracket assembly was placed in position for curing.