Shop temperature was 25 deg C and humidity was 42%.

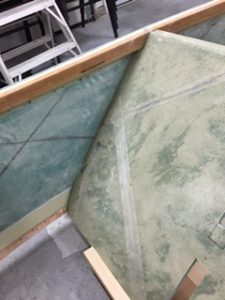

Epoxy was mixed and applied to the 8″ x 31″ layers ( 2 layers at 45 degree orientation) of BID cloth on top of the wax paper. A thin brush of epoxy was applied to the seatback joints.

Using the electric scissors, four 2″ x 31″ strips of glass/wax paper were cut. The strips were further cut to size, as required, and applied to all of the seatback/fuselage side joints (front left and right, aft left and right). The wax paper was removed and 2″ Dacron tape was applied (with epoxy) over all of the joints.

The seatback reinforcements were left to cure.